4 Most Common Allison 1000 Transmission Problems

Over the years, my shop has received so many calls from customers with numerous Allison 1000 transmission problems. Among the most common were wiring issues, fluid leakages, transmission going into limp mode, and shift selector issues.

Some problems may require professional attention for repair, whereas others need a few tweaking that you can do yourself. However, some issues may often require replacing certain parts to be fixed.

Diagnosing these problems may also seem overwhelming to most. But I’m more than thrilled to have been helping hundreds of people with their transmission woes. Let’s add to that with some diagnostic rundowns for Allison 1000.

troubleshooting Allison 1000 Transmission Problems

Understanding the signs of Allison transmission going out is the key to diagnosing and resolving them. Below, I’ve listed common problems I’ve encountered the most throughout the years and how to address them.

1. Wiring Issues

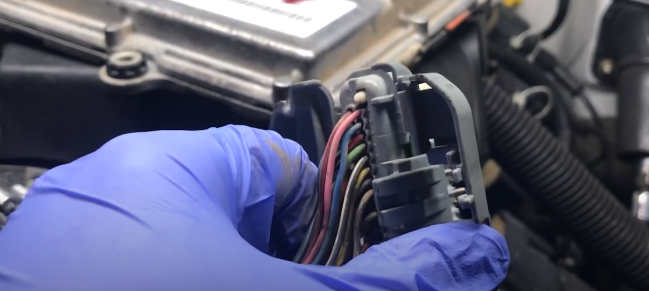

I get lots of visits from truck owners complaining about their Allison 1000’s control module going bad. But the funny thing is, I usually find the issue mainly with the wiring rather than the module. And they don’t even need replacements, either.

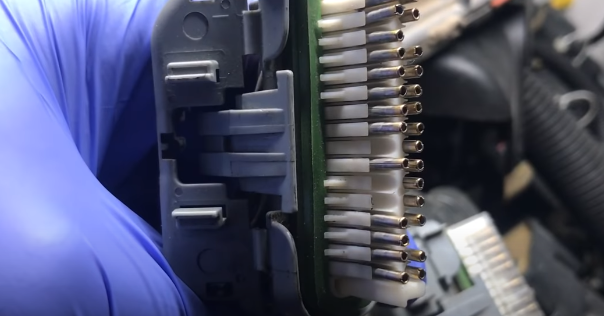

Now the question is how you know so. Well, all I do to be sure whether I need a new module or I just need to fix the wiring is check the harness. Just check the harness and the blue and red connectors.

- Your truck will likely have wiring harnesses up against the fan shroud with wires at a tight 90-degree angle.

- Due to the vibration and jerks of the truck, it pulls the pin past the lock, causing an intermittent connection.

- You’ll want to ensure the blue and red connectors are firmly pressed against the bottom of the lock guide, which is the clear and red thing, and firmly into the pins.

- Check all the pins. You’ll probably find a couple of them dislodged. So, just push those back in.

- Then put a little dielectric grease in there and plug it back up.

This way, you should be able to fix 99% of your TCM problems with your Allison 1000.

2. Fluid Leakages

Over the years, I’ve observed that fluid leakage issues have more to do with Allison 1000’s 5-speed models than 6-speed ones.

To be more precise, I’ve found this more frequently in older 105 Duramax and similar trucks the transmission is meant to use with. Their design has a weak point in the rear tail stock housing, which is usually the main troublemaker.

Look at the area I’ve pointed out in the below image. A hairline fracture on the side of the housing can cause a significant leak and drain your entire transmission fluid in a matter of minutes.

And guess what? With no fluid in your transmission pan, the Allison 1000 is destined to fail. I’ll only blame the housing’s design for this. It just isn’t strong enough to withstand high torque or acceleration, which may cause it to crack easily.

The best fix I’ve found is replacing the 5-speed transmission’s weaker housing with that of a newer 6-speed one. The latter is the former’s direct substitute with a heavier finned rear output shaft housing, which is much stronger and handles higher acceleration forces without trouble.

However, carrying out this replacement is no DIY job, and you must seek professional help to ensure proper installation.

3. Stuck in Limp Mode

Allison introduced the limp mode feature in the 1000 transmissions in the mid-2000s. Basically, it was meant to lock the transmission into the third gear when potentially severe damage is detected, which is good.

However, the problem is the range sensor often misreads the ratio due to slips caused by excessive pressure and overheating. This eventually leads to the transmission getting stuck in limp mode.

And inspecting the Allison 1000 multiple times, I’ve found a flaw in its design, which can often play a big part in leading to this sort of problem.

Its range switch connects to the solenoid valve bodies, switching between Park, Reverse, Neutral, and Drive 2, 1, and 3. The problem is this switch is external and sensitive enough to read the gear ratio where it isn’t supposed to when struggling to cope with heavy loads.

Unfortunately, you’ve got nothing to do once your truck gets stuck in the limp mode. You’ll either have to replace it entirely or ask the company for a rebuild. Only proper maintenance can prevent it in the first place.

4. Shift Selector Issues

I’ve seen many faces of Allison transmission shift selector problems over the years. Delayed or hard shifting is the obvious top among those, just like in every other automatic transmission. And the fix often lies within the transmission fluid, often needing a top-up or replacement.

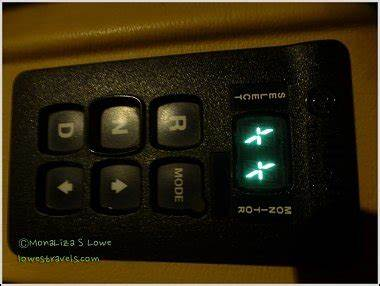

Other than that, having no power and the shift selector flashing are the two other common problems I’ve seen people run into. Here’s what you can do about them:

- First, try disconnecting the power cable going into the selector and plugging it back again. If that doesn’t work, pry open the housing around the wires and reconnect or replace any dislodged or broken wires. Also, check for blown fuses and replace them as needed.

- A flashing shift selector can indicate a more serious issue, including a failed transmission control module, which requires diagnosis by obtaining the relevant DTC codes. So, don’t hesitate to take your truck to a trusted repair shop or dealer.

Frequently Asked Questions (FAQs)

I’ve answered a few common questions regarding Allison 1000 transmission below. Check them out if you have further queries.

Lags, rough shifting, leaks, burnt smells, and check engine lights coming on are some of the primary signs you should expect. Besides these, I’ve seen a lot of cases where trucks have delays when changing gears, accelerating, or activating the exhaust brake.

Regular maintenance is the best I’d suggest to prevent transmissions from going into limp mode. This may include ensuring the correct fluid levels, checking the wiring, and clearing the linkage. I’d recommend doing scheduled band inspections and full-scale tune-ups as well.

Most often, the looseness with use is what I’ve seen causes the fluid hose fittings to leak. You can get rid of it just by checking the tightness regularly. However, in more serious cases, the culprit is a damaged drain plug, a broken seal, a cracked fuel line, or a bad torque converter.

Conclusion

To recap, here are the 4 Most Common Allison 1000 Transmission Problems:

- Wiring Issues

- Fluid Leakages

- Stuck In Limp Mode

- Shift Selector Issues

While the ones I’ve discussed are the most frequent, other issues could arise in this intricate automatic transmission. For instance, the torque converter may hit a snag, the stator may hinder heat management, and even the frictional elements may get awry with added power.

Yet, regular maintenance and timely intervention can make all the difference in keeping your Allison 1000 running smoothly.

Video References

Spartan Autoworx

DG’s Pro Tech

Certification: BSc in Mechanical Engineering

Education: Mechanical engineer

Lives In: 539 W Commerce St, Dallas, TX 75208, USA

Rasel is an auto mechanic student and writer with over half a decade of experience in the automotive field. He has worked with top automotive brands such as Lexus, Quantum, and also owns two automotive blogs autocarneed.com and taxiwiz.com.